Extruded parts & cold-formed parts – Areas of application

Cold-formed parts are used in almost every manufacturing sector today. Fasteners, such as nuts, bolts and screws, are among the most common parts made using the cold forming process. Tigges produces precision-made cold-formed and extruded parts for customers from a diverse range of backgrounds such as the automotive industry, mechanical and electrical engineering, aerospace, telecommunications, construction, and energy production.

Cold-formed parts are our business

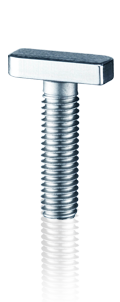

Special screws and custom-made bolts can be made to your unique specifications from a sample or drawing or through in-depth discussion with our skilled team of designers and engineers.

We can make the special fastener you have in mind, and we are committed to finding you the best and most cost-effective solution, whatever your requirement is.

How are cold-formed parts made?

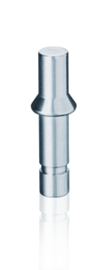

Cold forming is a high-speed forging process where usually coiled wire at room temperature is precisely sheared to length, and then moved through a succession of tool and die cavities to displace the working metal, either larger/smaller in diameter, longer/shorter in length or to remove small amounts of material by trimming or piercing.

Advantages of high-precision cold-formed parts

There are several advantages of high-precision cold-formed parts. In industries where there is no room for error – construction, aerospace and car manufacturing, for example, this is one of the most important factors.

Compared with hot forming, cold-formed parts have higher tensile strength thanks to the cold working process. Because they can be manufactured quickly, high-precision cold-formed parts also tend to be produced at lower cost than hot-formed parts.

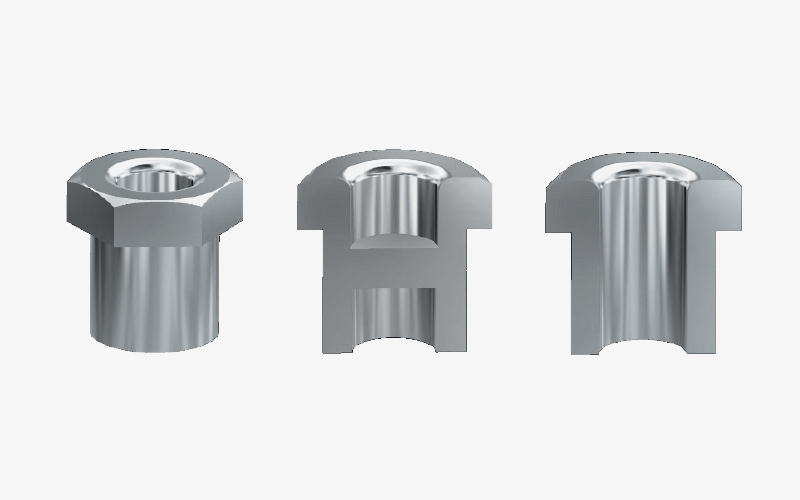

Extruded cold-formed parts

Extrusion is a cold forming process which gained more and more importance over the past decades. With the latest cold forming technology in terms of machinery and tooling and the right tool design, it is today possible to cold form parts which in the past only have been able to be produced by slow and costly CNC turning processes.

Although our standard range is vast, sometimes custom-made cold-formed parts are the best solution. Maybe you require extra large heads, different size threading or unusual shapes or parts made of special materials. Whatever your needs, Tigges can help you to realise your requirements.