Manufacturing: Nothing coincidental

in our production processes

Productivity with "zero ppm"

Nothing is random in our production processes. Our strict quality standards begin with the raw material, which is drawn in-house and then passed to the cold forming machine. Our state-of-the-art machinery is unparalleled worldwide in terms of its efficiency and speed.

Subsequently, if required, all secondary operations such as additional turning are done on our wide range of equipment. The same applies to thread rolling, where we can always create customized solutions in addition to our standard threads.

Finally, the surface treatment ensures a perfect finish, both technically and visually.

This productive workflow allows for no random errors thanks to the vast experience and precise process controls carried out by our dedicated team of specialists.

Tool design

Tool design is the heart of any special parts production. Our cold-formed parts are manufactured on part formers with up to 6 stations. Here, a tool set can consist of up to 50 different tools. From design and drawing to the finished tool, it takes experience, technical expertise and knowledge of material flow to ensure smooth, long-term operation.

Our team of tool makers and designers have a mass of practical knowledge. They not only truly know their craft, but they also turn innovative ideas into reality in order to offer our customers improved efficiency. For example, they come up with solutions that make processes much more cost-effective than standard processes. We then pass this benefit on to our customers.

Wire drawing

Quality right from the start: we carry out wire drawing in-house, so, the quality of the drawn wire that we use is in our own hands. With our integrated annealing furnace, the physical properties of the final material can be monitored, documented and stored for each individual customer.

With this process, we not only guarantee consistent material quality but are also able to shorten delivery times.

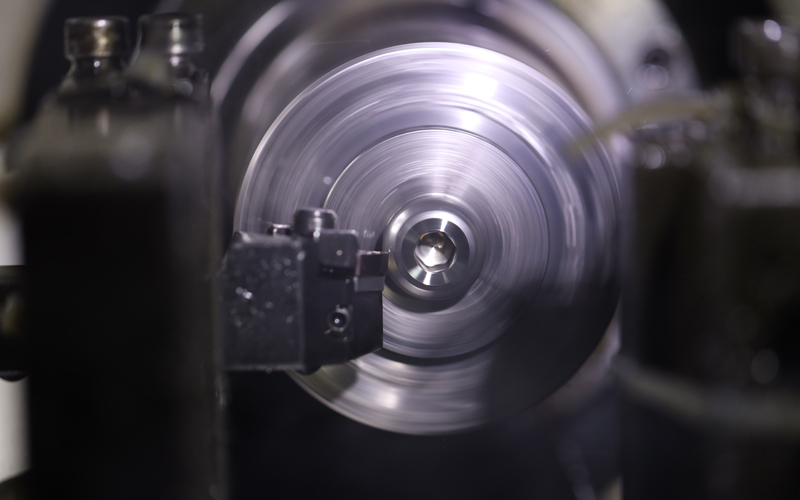

Cold forming

Our machinery provides world-class technology in the cold forming of wire to blanks. Among them are high-speed systems with a productivity of up to 100,000 parts per shift per day and cold formers with up to 6 stations, which can produce even complex geometries in a single operation.

With our technical know-how and interaction with new technologies, we have the skill to operate a cost-effective forming process for parts which could previously only be produced by CNC lathes. In addition to providing substantial reductions in production costs, the physical properties of the finished product are improved, for example by increasing its strength.

Harden

With our own in-house vacuum heat treatment plant, we are one of very few fastener and cold-formrd parts manufacturers worldwide to offer not only the production but also high-end vacuum heat treatment for the most demanding customer requirements.

By having our own raw material processing plant as well as heat treatment facility, we can design and control even the tightest mechanical properties needed for our parts.

Further, it gives us complete control over the entire manufacturing process from A to Z to produce not only components with consistent quality our customer can rely on, but also enables us to follow tight delivery time schedules when needed.

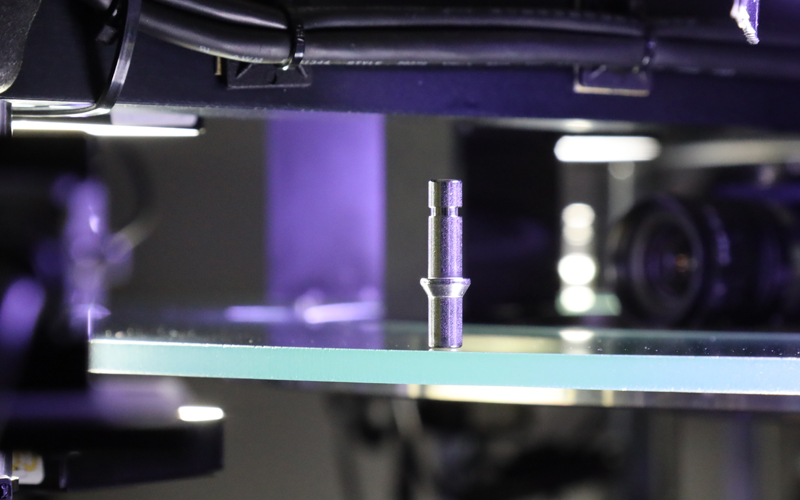

Secondary operations

Our wide range of secondary operations equipment, such as auto lathe and CNC turning, drilling, slotting and centerless grinding, allows products to be customised to suit your specific requirements. All the necessary machinery and equipment are available, meaning we can ensure continuous process accuracy while remaining flexible and competitive.

Turning

As our core capability is the design and manufacturing of even the most demanding cold-formed parts, we do not stop here but are able to offer secondary machining with auto-lathe, CNC and machining centres to produce shapes, designs and tolerances outside of the cold form possibilities.

From having additional grooves, machined head surfaces to tolerances as low as 10 microns, we are able to produce parts which require additional turning, drilling and machining processes. This is all done under one roof and combined with automatic feeding systems to produce high-volume parts efficiently.

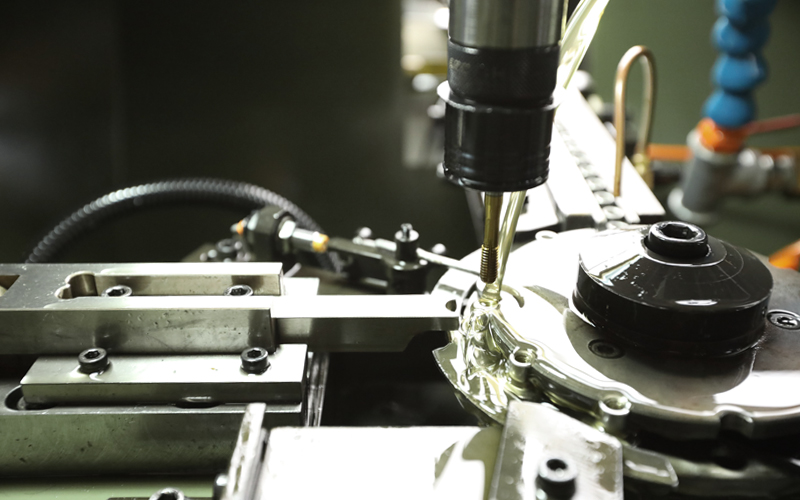

Thread rolling and thread tapping

With the wide range of thread rolling and tapping machines available, we match the most efficient and quality consistent thread rolling process to each product.

From mass-produced high-speed flat die rolling of shank threaded fasteners to thin-walled hollow-rolled threads done on multiple rollers to automatic thread tapping machines for internal threads, we have them all under one roof to use the best possible thread rolling process for each product.

And, of course, we offer any standard threads from DIN, ISO, JIS, ANSI to any special thread required, matched with tolerances designed to fulfil even the most stringent requirements.

Passivation and washing

Even stainless steel will not be completely corrosion-free without the right passivation process. By removing any foreign particles from the surface, passivation leads to a protective oxide layer which is less likely to react with air and cause corrosion.

With our own passivation facility, we can ensure that the stainless steel parts produced and supplied are really corrosion-resistant. We can also control the level of surface roughness and visual appearance to provide polished stainless steel fasteners and components that meet our customers requirements, both in terms of corrosion and visual result.

Finishing

To improve the corrosion resistance of the finished fasteners, our production is followed by surface treatment. Here, for example, the products are finished by passivation – in technical terms by building up a shield against surface corrosion, and in optical terms by polishing the parts to achieve the desired finish.

We can also meet particular customer specifications with customized coatings and surface treatments.