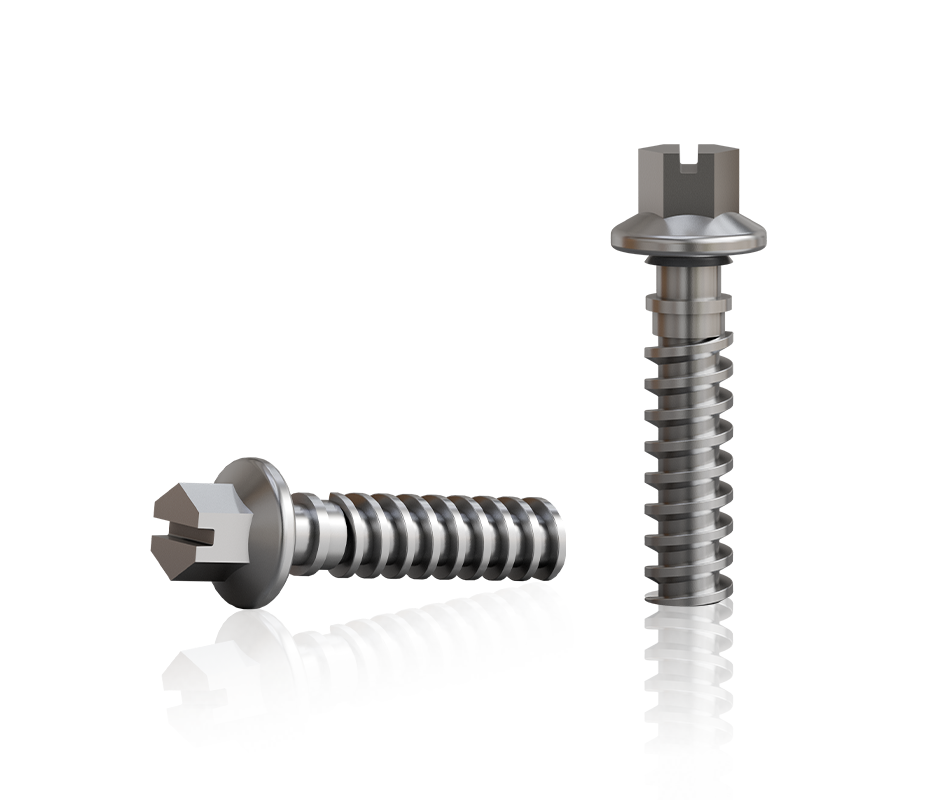

Screws, nuts and fasteners for the automotive industry –

Precision and resilience

In the automotive industry, screws, nuts and fasteners have to deliver top performance. They secure engines, gearboxes, chassis, car bodies and interiors and have to withstand enormous forces, vibrations and temperature changes. Maximum strength, reliability and precision are crucial – because every connection contributes directly to the safety and performance of the vehicle.

Tigges supplies customized fasteners for OEMs and suppliers. Our portfolio includes high-strength

Fasteners for electromobility – innovation and safety

Electromobility places special demands on screws, nuts and fasteners. In addition to traditional applications in vehicle construction, these include high-voltage battery systems, charging infrastructure and lightweight components.

Fasteners must not only be mechanically resilient, but also electrically safe, insulating or conductive – depending on the area of application. Weight reduction also plays a key role in optimizing the range and efficiency of electric vehicles.

Tigges offers innovative solutions for electromobility: from special brass screws and nuts for battery systems to lightweight aluminum and titanium fasteners and coated fasteners that prevent corrosion and specifically control electrical properties. Our fasteners are designed for maximum safety, precision and sustainability.

Product examples

Our services

We don’t just sell a product. We sell a solution. And we support you with comprehensive services for this solution. Together, we develop the ideal fasteners for your requirements through consultation and design. With our access to an exclusive supplier network, we also offer you optimized production costs and take on extensive shipping and logistics tasks for you.

Our team at Tigges can help you

Use our contact form

Technology (M) Sdn. Bhd.

Telefon: +60 (0) 5 29 22 781

Fax: +60 (0) 5 29 11 050

E-Mail: info@tigges.com.my