Global perspective with German roots

For almost 100 years, Tigges has stood for quality and expertise for discerning customers worldwide. We cultivate our virtues as a German family business with personal responsibility, quality awareness and service orientation. Our successful growth, healthy figures and satisfied employees reflect an ambitious self-confidence that makes us an exceptional supplier.

Foundation of Lebrecht Tigges KG in Wuppertal, Germany

Initially machining production of turned parts.

Start of cold forming of screws

Expansion of the production of stainless steel screws in the 1960s. Among other things, over 1 million stainless steel screws were produced by Tigges for the construction of the Olympic Stadium in Munich. Other references include the Hamburg Elbe Tunnel and the UN building in Vienna.

Foundation of Tigges Stainless Steel Fasteners (M) Sdn. Bhd.

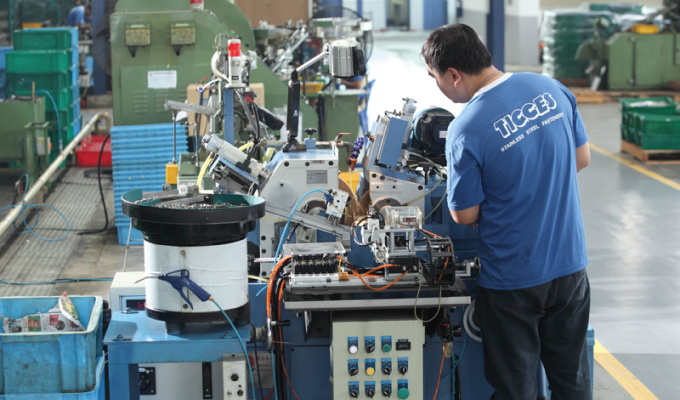

Construction and commissioning of a new production hall with a floor area of 8,000 m² for the manufacture of stainless steel Standard screws for the European market.

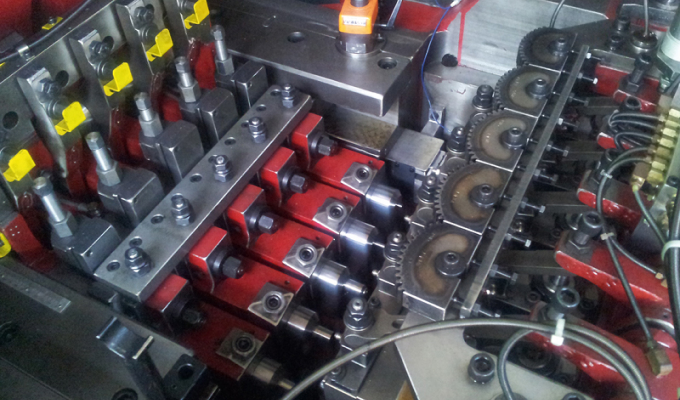

Commissioning of the first multi-stage press (three forming stages)

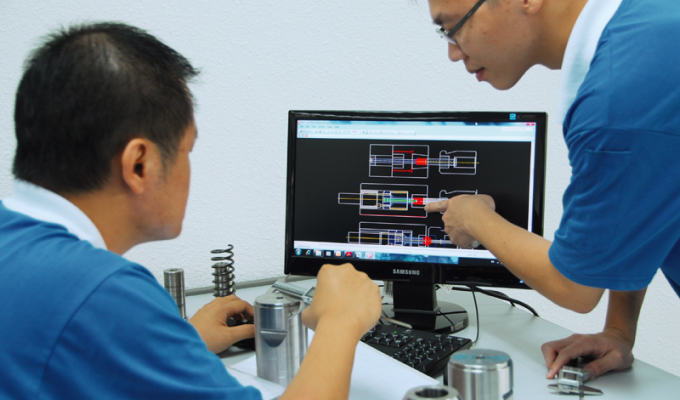

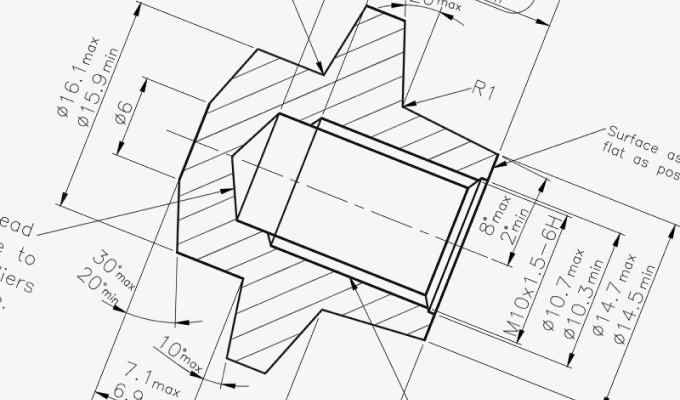

Establishment of an in-house development department and start of production of special parts.

Opening of “Tigges Fasteners Trading Sdn. Bhd.” near Kuala Lumpur

Placement of a sales and logistics center with its own warehouse in the country’s main industrial center.

Certification according to ISO 9002

Expansion from previously only stainless steel to other material types such as steel and aluminum.

Commissioning of the first 5-stage press

Establishment as a “niche manufacturer” of high-quality special parts for direct customers from industry.

Expansion of the service area

Development of an internal service department; establishment of quality management for commercial products and addition of packaging sets and assemblies to the portfolio.

Installation of a 100% final inspection

Successful entry into sensitive markets with the highest quality requirements.

Commissioning of the first 6-stage press

Rise to the top of the world in the production of very complicated formed parts.

Certification according to TS16949 and commissioning of a new production facility in Ipoh

- We are gaining a strong foothold in the automotive industry.

- The capacity will be expanded with an additional 19,500 m² of production space.

Expansion into Japan

Opening of the regional office and warehouse in Kobe.

Change of name to “Tigges Fastener Technology (M) Sdn. Bhd.”

Positioning as a comprehensive system provider; commissioning of the first CNC re-turning machine; further specialization in special parts.

Investments in post-processing equipment

Expansion of manufacturing expertise for high-precision special parts.

Investment in our own hardening shop

Cost and quality optimization through the installation of an in-house hardening furnace.

Launch of the new production facility at the second site in Ipoh

Doubling of the floor space to 40,000 m².