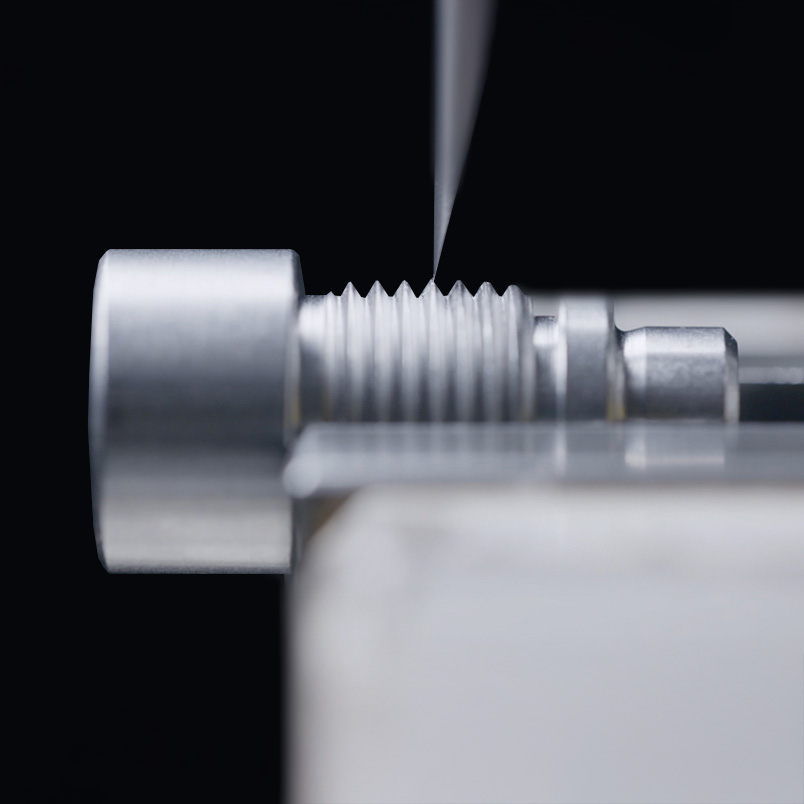

Precision and quality down to the last detail

The German term “Wertarbeit” describes a product that delivers what it promises. As a company with German roots, we are committed to this claim and achieve it with consistent quality management.

Our screws stand for maximum reliability – thanks to consistent quality management from production to delivery. Each production step is monitored by state-of-the-art process and final inspections.

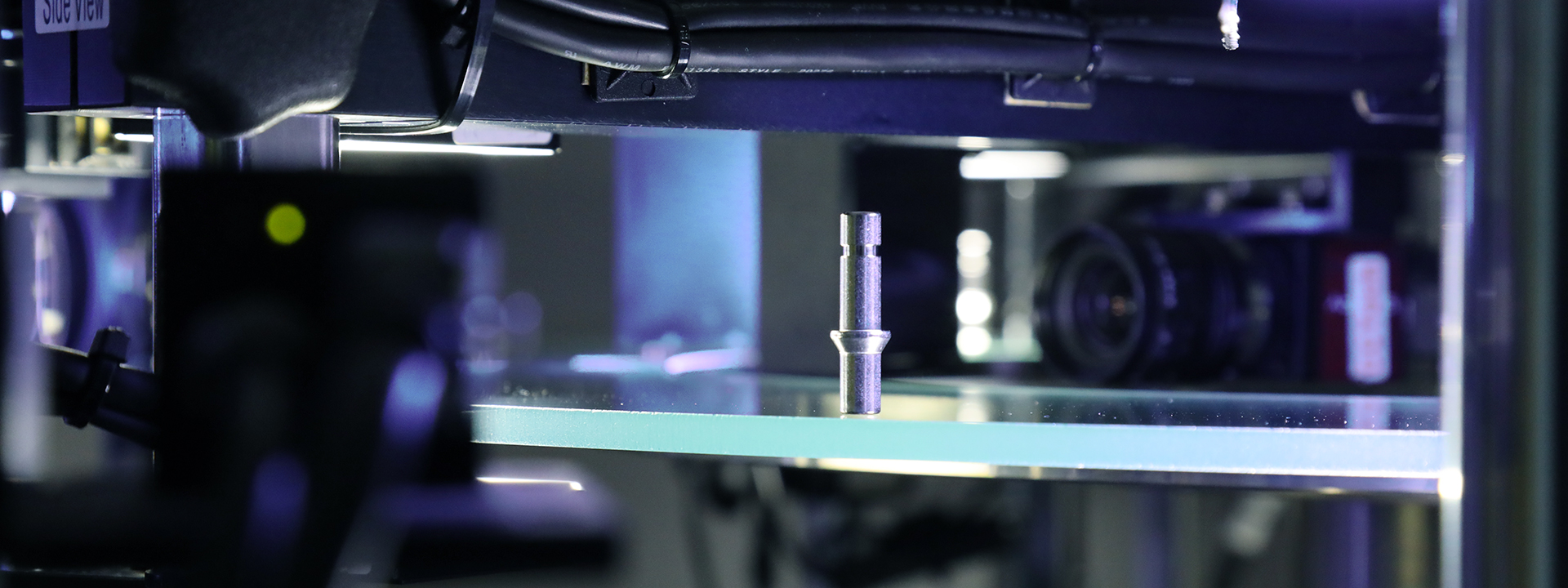

Using camera-supported 100% sorting, laser and eddy current testing as well as AI-supported evaluation, we ensure that every part meets our strict standards. We also test corrosion resistance and mechanical strength in our in-house test laboratory – for products that you can rely on in the long term.

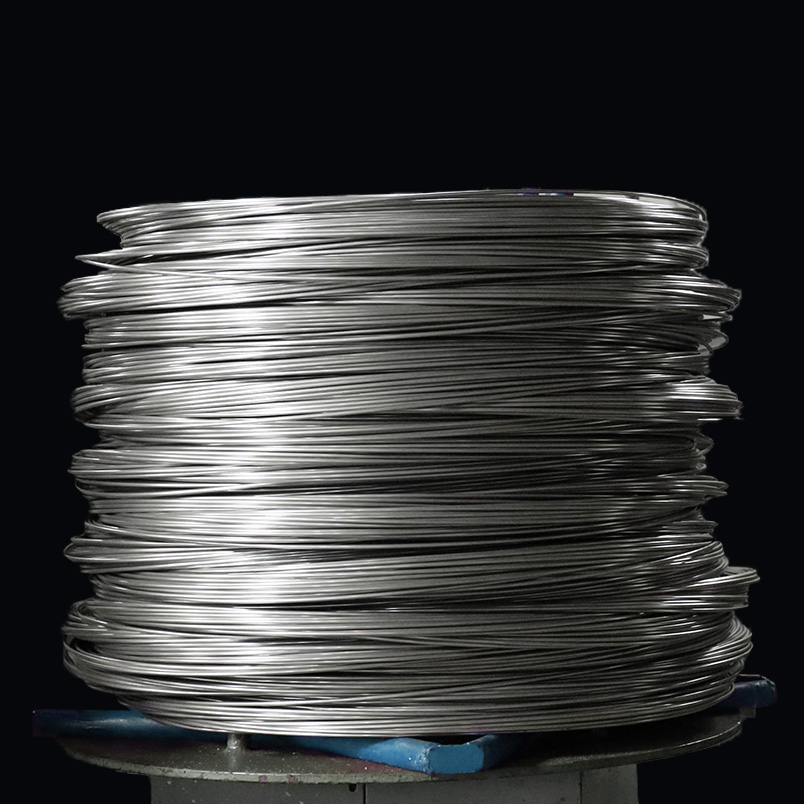

Quality of incoming goods

The incoming goods inspection checks the incoming material before it enters the production process. But it is not the first step in quality assurance. Our supplier management already defines the production processes of our suppliers. This means that the quality concept is already part of the value chain before it reaches our production.

Reliable processes through SPC

We use SPC to monitor and ensure the process capability of our production in the long term. This statistical process control does not focus on the flawlessness of the tested component, but on the production process itself, which is continuously evaluated using statistical methods.

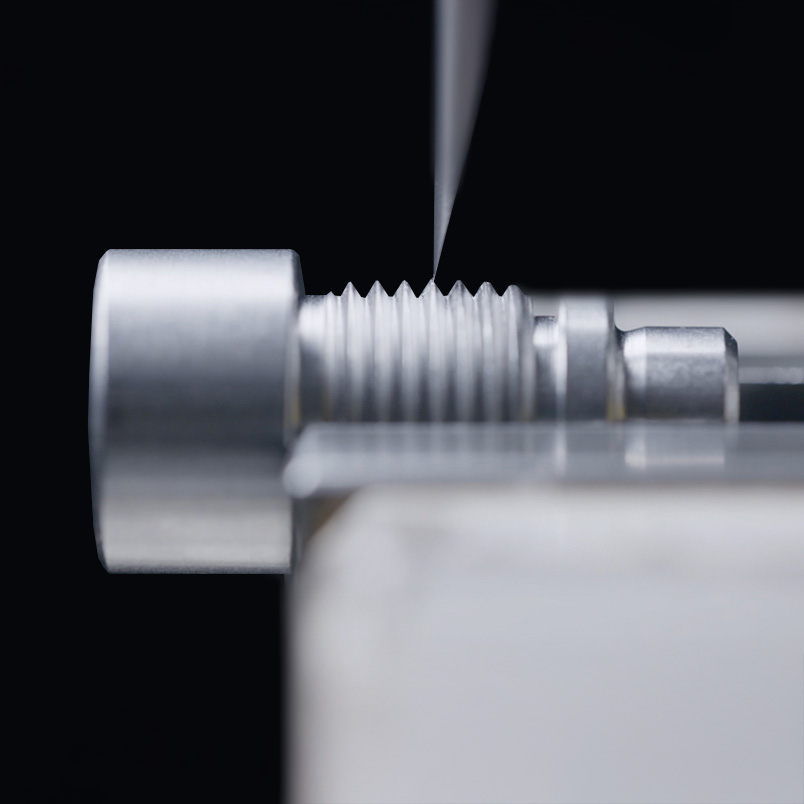

Process control

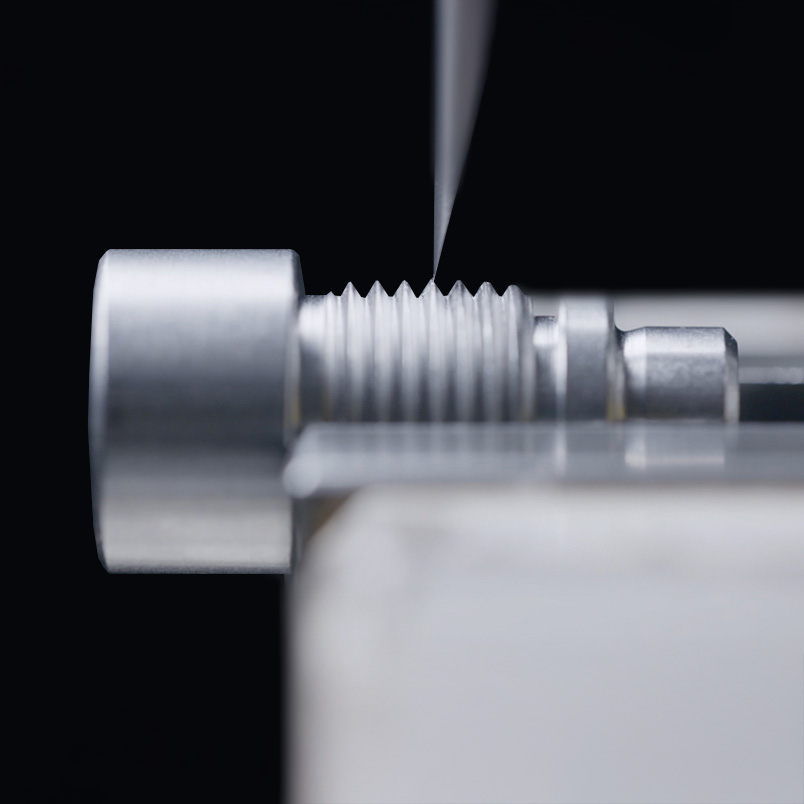

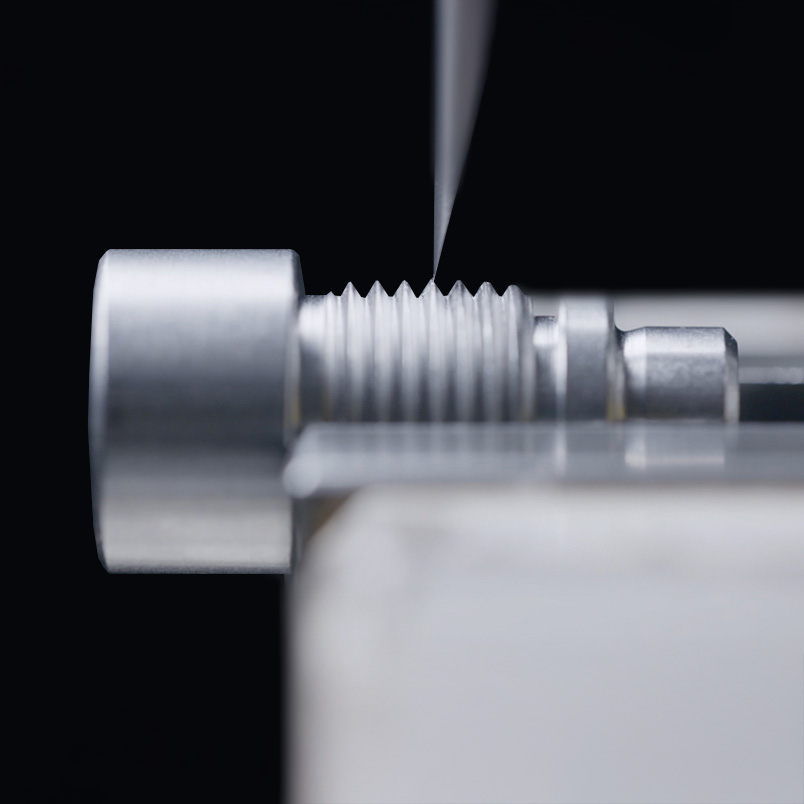

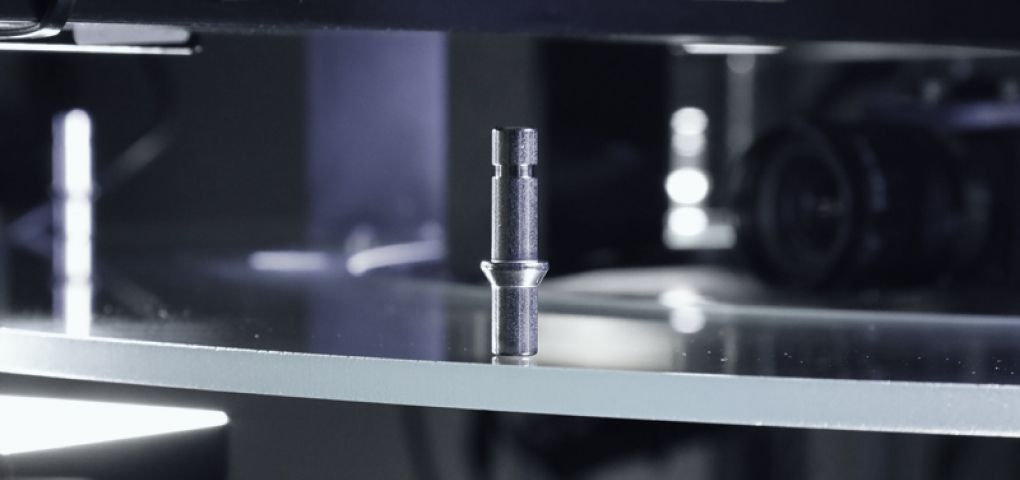

Process inspection is the key to assured quality, especially for larger production batches. With rigorous in-process inspection of every manufacturing process, we can ensure that parts are delivered to our customers with consistently good quality so that they can use our parts safely, without uncertainty about parts that may be out of specification and disrupt their assembly process.

Using state-of-the-art measuring equipment, such as optical inspection systems, we can take multiple measurements at the touch of a button. We test to produce not only parts within specifications and tolerances, but also parts that require a specific CPK (process capability index) value, which is monitored and recorded for each manufacturing process.

Outgoing goods quality

In addition to our strict process control, no product leaves our premises without being checked and recorded for all dimensions, tolerances, mechanical properties and even appearance requirements. In this way, we ensure that our customers only receive parts that fully comply with the specifications.

Thanks to our own laboratory, we are able to use any measurement technology – from projector, contracer, hardness and tensile tests to automated optical inspection.

Individual test plans are drawn up for each product, in which not only all tolerances, mechanical properties and appearance requirements are defined, but also the specification of the tests that are carried out before release and delivery to our customers.

PPAP according to IATF 16949

As an IATF 16949-certified company, we offer PPAP, a professional production part approval process for sampling series parts. For product and process approval, we provide the required measurement, material and functional reports on standardized forms – also paperless – and ensure an efficient exchange in the approval process.

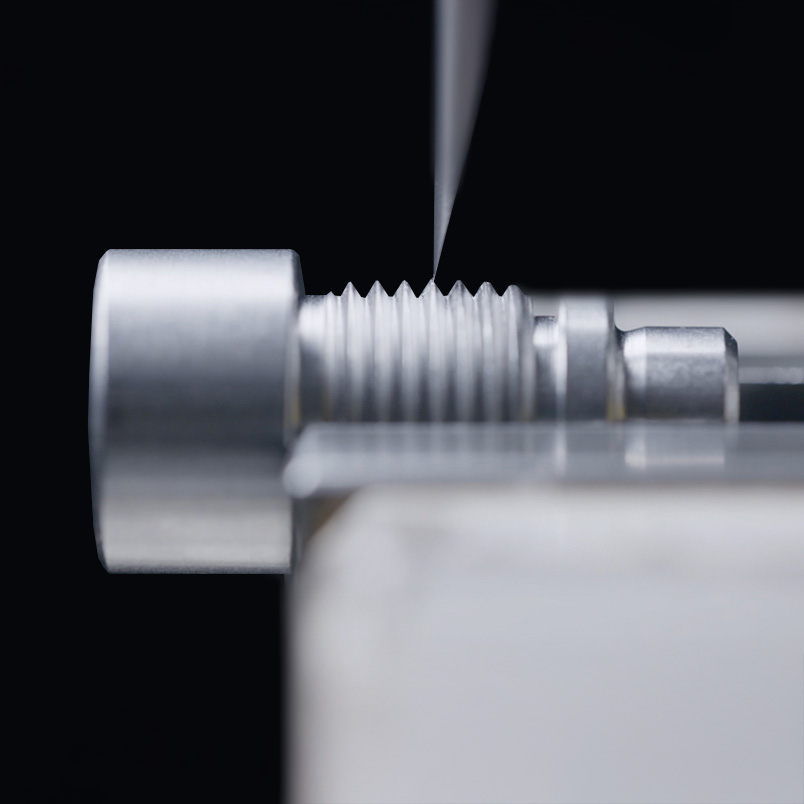

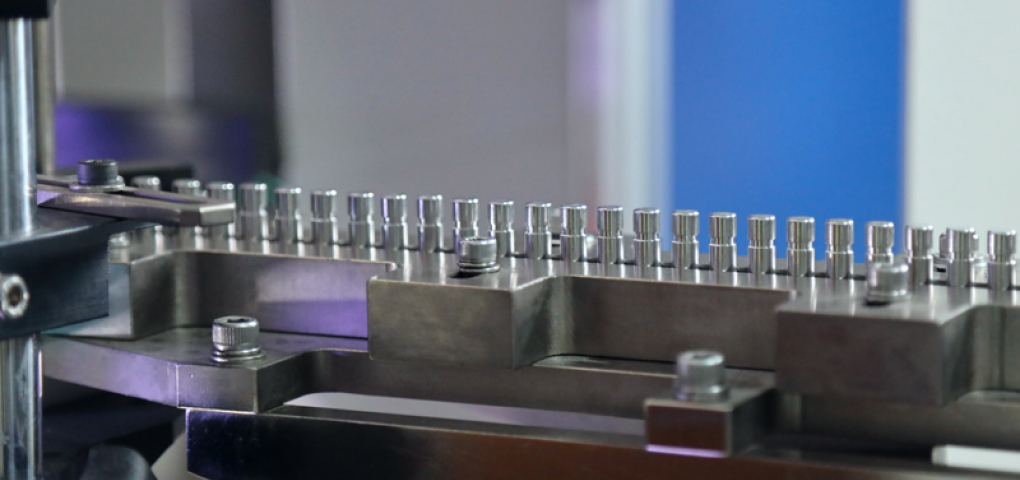

100 % control through optical sorting

In many cases and in today’s automated assembly lines, 100% inspection has become the norm to ensure that parts are delivered close to “zero ppm”. To achieve this, state-of-the-art automated inspection machines are required.

With a variety of optical inspection machines and even eddy current machines for testing internal cracks and hardness, we can deliver parts that are 100% inspected. Our machines inspect every single part with a throughput of up to 500 pieces/minute to enable high volume inspection.

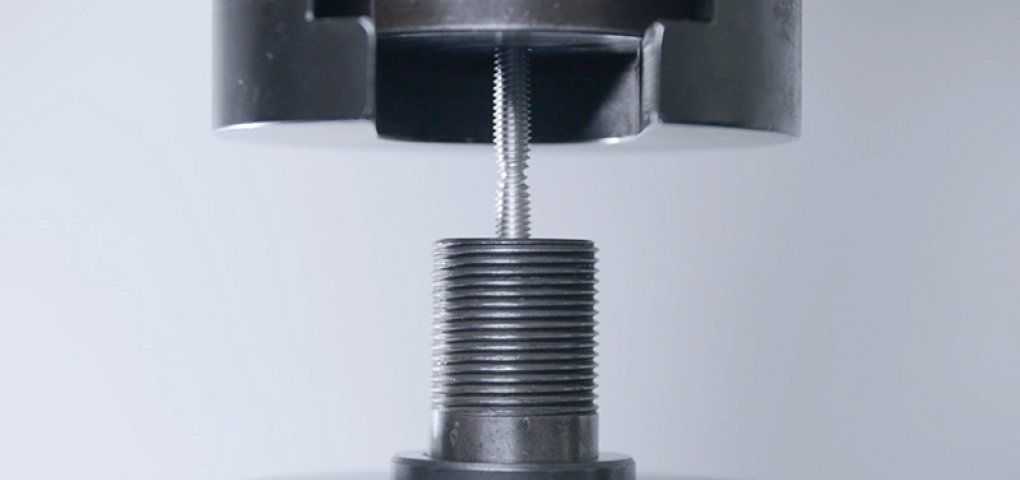

Mechanical tests

An extensive range of equipment is available for testing the mechanical load-bearing capacity, with which the physical product properties such as tensile strength, torque and hardness are tested. The testing department also serves as a laboratory for the in-house development of product variants, e.g. for optimized Standard screws with increased strength.

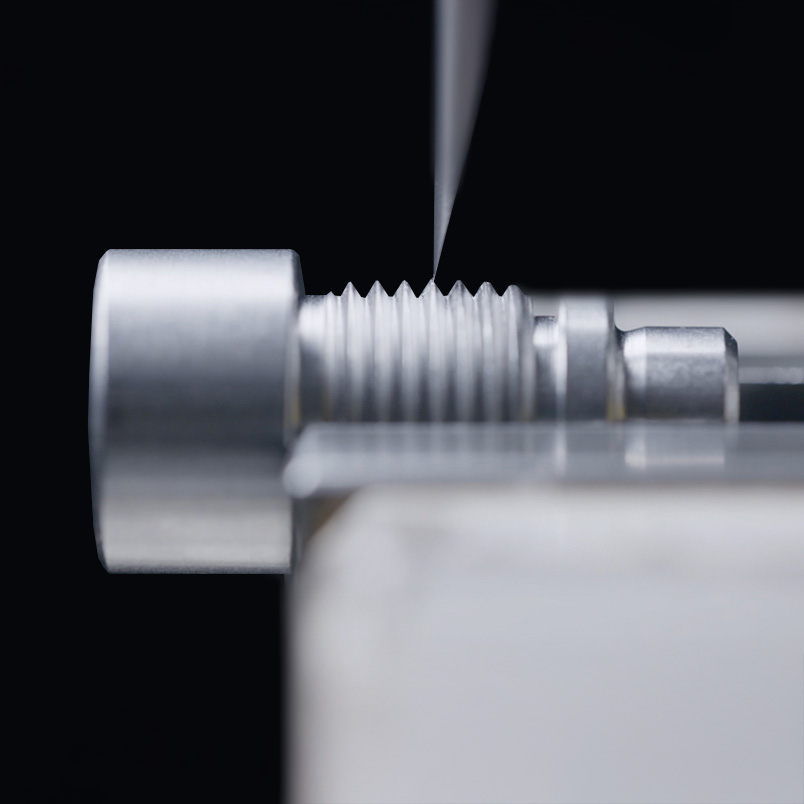

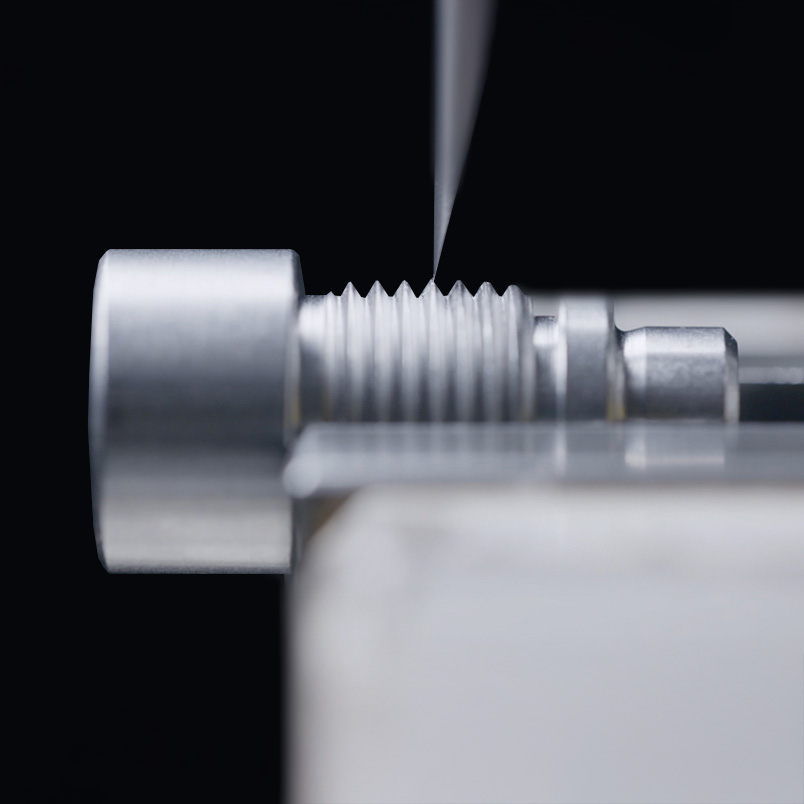

Precision down to the µ

To ensure dimensional accuracy, we use state-of-the-art measuring methods, including a Mitutoyo Contracer for high-precision contour measurement, camera systems and digital projectors that check up to 500 parts per minute with 20 µ accuracy. This enables us to meet the required product quality, which benefits your production reliability.

Sustainable quality

Our experience with materials and expertise in surface treatment results in connecting parts with a perfect balance of application, resistance and cost-effectiveness. A test laboratory with chemical-physical testing equipment is available for this purpose, including a salt spray system, which provides information on corrosion resistance and gives us a significant competitive edge, e.g. in the offshore industry.

Certified quality

Our quality management is certified in accordance with ISO 9001 and IATF 16949. In addition, we meet and exceed many industry and company specifications.

Test procedure

An extensive range of equipment is available for testing the mechanical load-bearing capacity, with which the physical product properties such as tensile strength, torque and hardness are tested. The testing department also serves as a laboratory for the in-house development of product variants, e.g. optimized Standard screws with increased strength.

To ensure dimensional accuracy, we use state-of-the-art measuring methods, including a Mitutoyo Contracer for high-precision contour measurement, camera systems and digital projectors that check up to 500 parts per minute with an accuracy of 20 µ. This enables us to meet the required product quality, which benefits your production reliability.

Special measures

As an IATF 16949-certified company, we offer PPAP, a professional production part approval process for sampling series parts. For product and process approval, we provide the required measurement, material and functional reports on standardized forms – also paperless – and ensure an efficient exchange in the approval process.

In modern assembly lines, 100% inspection is essential in order to deliver virtually flawless parts. State-of-the-art testing machines make this quality assurance possible. Optical inspection systems and eddy current technology detect even the smallest internal cracks or deviations in hardness. With an inspection speed of up to 500 parts per minute, our machines guarantee reliable results and efficient inspection of every single component.

Our quality standards

Our expertise in materials and surface treatment ensures optimum connecting parts with an ideal balance of usability, resistance and cost. A modern test laboratory with chemical-physical testing equipment, such as a salt spray system for corrosion testing, ensures quality and gives us a head start, for example in the offshore industry.

Our quality management is certified in accordance with ISO 9001 and IATF 16949. In addition, we meet and exceed many industry and company specifications.

Our team at Tigges can help you

Use our contact form

Technology (M) Sdn. Bhd.

Telefon: +60 (0) 5 29 22 781

Fax: +60 (0) 5 29 11 050

E-Mail: info@tigges.com.my