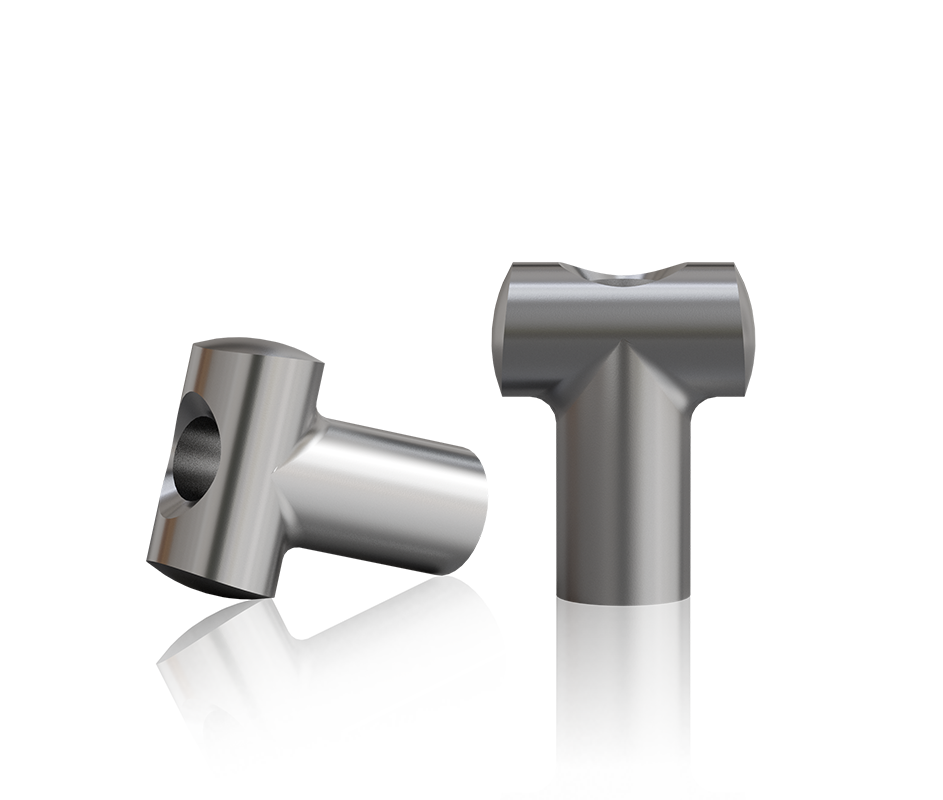

T-bolts & trunnions

With our many years of design and manufacturing experience, we can also offer the most demanding cold-formed designs, such as T-bolts, T-bolts and trunnions, which are used in the automotive industry and other sectors.

Our team of engineers designs individual cold forming tools for up to 6 stations. In addition, we can post-process complex geometries using in-house CNC lathes and machining centers. This enables us to offer complete solutions – from design and prototyping, in-house laboratory testing and mass production to heat treatment and, if required, optical sorting.

Tell us your requirements for T-bolts made of stainless steel, carbon or alloy steel. We offer a solution that meets all your requirements.

Contact usData and specifications

We manufacture your matching t-bolts head

The head of a t-bolt is crucial for its safe and reliable application. Its characteristic T-shape ensures that the screw sits firmly in a groove or rail without twisting. It is important that the head is precisely matched to the respective profile size so that the load is evenly distributed and no damage occurs. In addition, the surface should be cleanly finished and, depending on the area of application, protected against corrosion. A precisely manufactured screw head not only makes installation easier, but also guarantees a permanently stable connection in a wide variety of constructions. There are also flat head shapes, which are particularly suitable for tight installation situations, as well as reinforced heads for higher loads. Special variants with rounded or chamfered edges also make installation easier and protect the profile. Choosing the right head shape is crucial for the accuracy of fit, the stability of the connection and the service life of the entire construction.

T-trunnions – a specialty from Tigges

A trunnion stud differs from a solid stud in that it has a central hole, which saves weight or provides space for pipes, cables or lubricants. When selecting a bolt, particular attention should be paid to the material quality and wall thickness, as these determine the load-bearing capacity. Walls that are too thin can impair stability, while a precisely manufactured bore ensures even force distribution. Depending on the area of application, attention should also be paid to corrosion protection and suitable surface treatment. The T-hollow bolt combines the advantages of a trunnion with the special shape of a T-bolt. The central bore reduces weight or creates space for cables, liquids or lubricants, while the T-shaped head geometry ensures secure, torsion-proof fixing in grooves or rails. This combination makes the T-shaped trunnion a flexible solution for designs where stability and functionality are equally important. It is important that the head and bore are precisely manufactured to ensure both mechanical strength and ease of installation. This results in reliable connections even for demanding applications.

Thread types

T-bolts and trunnions are available with different thread forms, each offering specific advantages. The metric standard thread is the standard and is used in most designs as it is universal and readily available. Fine threads are particularly suitable for precise adjustments and applications with high vibration loads, as they offer better self-locking. Special threads, such as trapezoidal or round threads, are used where high forces are transmitted or frequent movements take place. The choice of the right thread form therefore always depends on the area of application – from mechanical and plant engineering to vehicle technology and assembly and fastening systems.

Properties

Head type is often one of the first considerations when designing a fastener. Some of the many head shapes that can be achieved through cold forming technology include countersunk, cylindrical, hammerhead, hexagon and many others.

Special screws with oversized heads are our specialty; these customer-specific parts cannot be produced using conventional cold forming processes.

A perfect fit for your industry

For demanding fields of application

Our team at Tigges can help you

Use our contact form

Technology (M) Sdn. Bhd.

Telefon: +60 (0) 5 29 22 781

Fax: +60 (0) 5 29 11 050

E-Mail: info@tigges.com.my