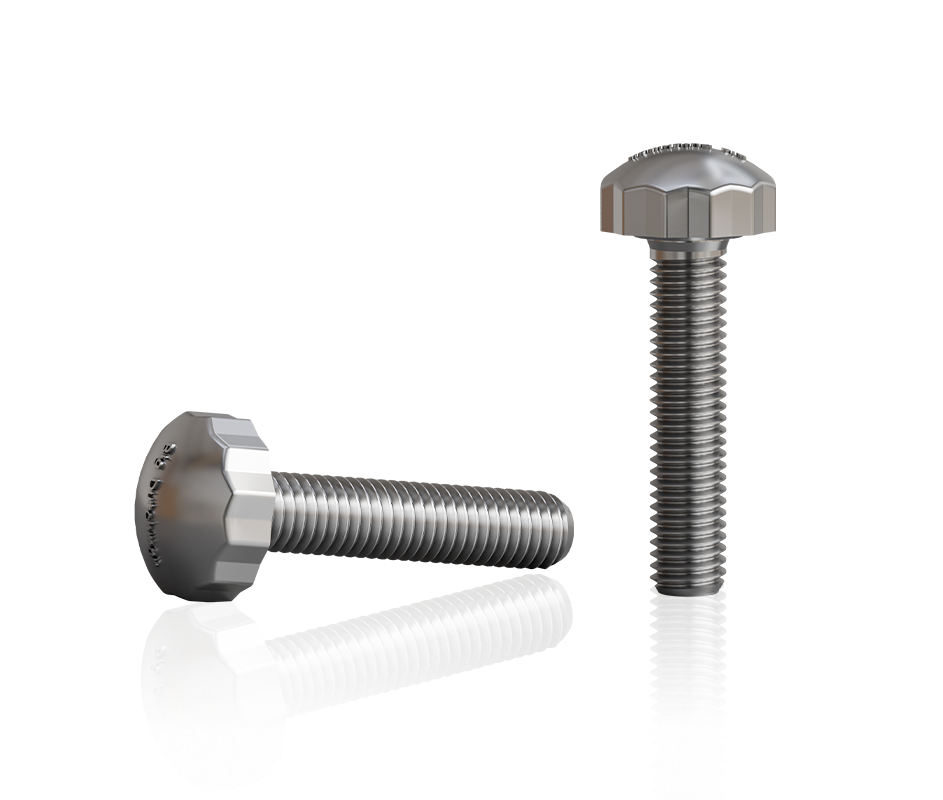

Special screws and special screws

Special screws and custom-made screws can be manufactured to your individual specifications based on a sample or drawing or following advice from our qualified team of engineers.

We develop and design the fasteners you specifically require and strive to find the best and most cost-effective solution for you that best meets your requirements.

Contact usData and specifications

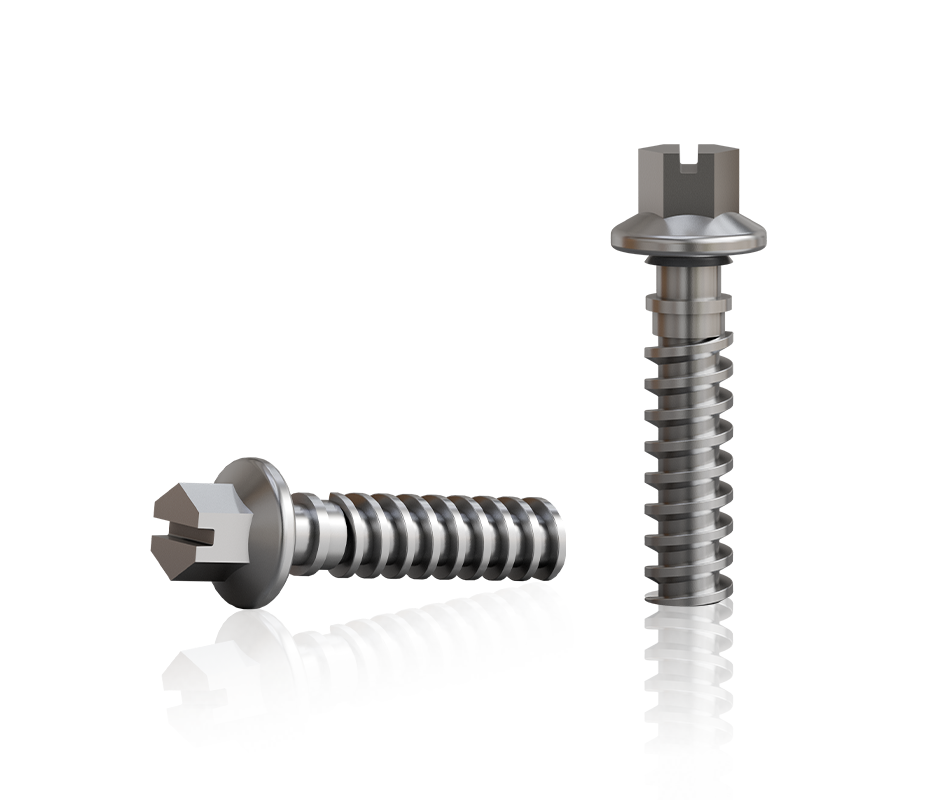

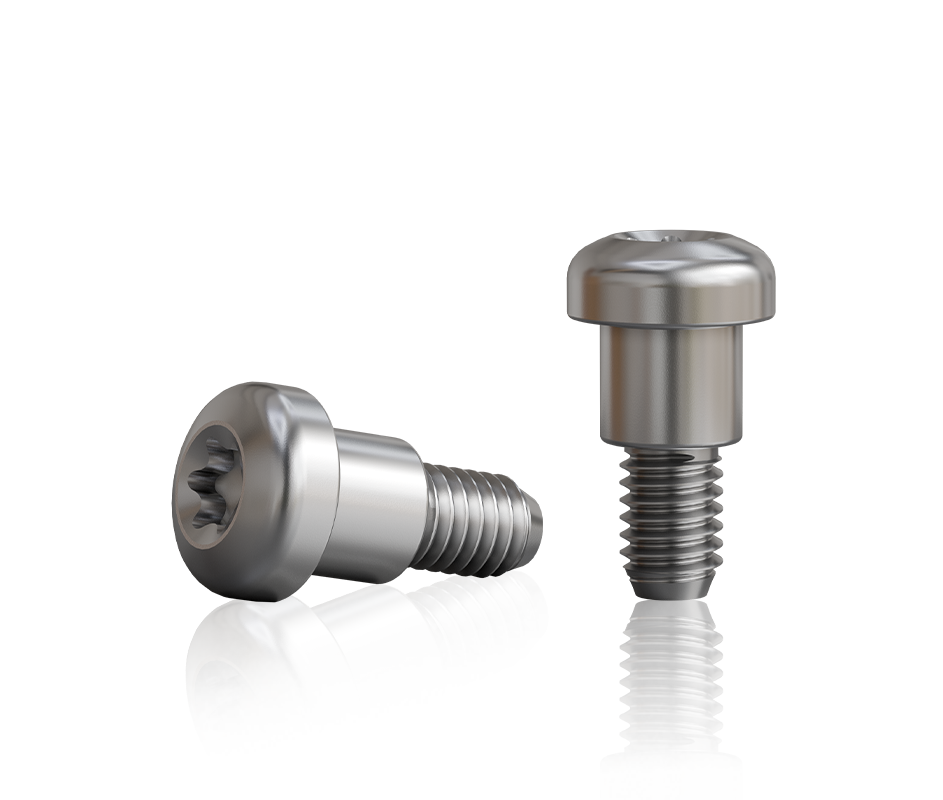

Head

Head type is often one of the first considerations when designing a fastener. Some of the many head shapes that can be achieved through cold forming technology include countersunk, cylindrical, hammerhead, hexagon and many others.

Special screws with oversized heads are our specialty; these customer-specific parts cannot be produced using conventional cold forming processes.

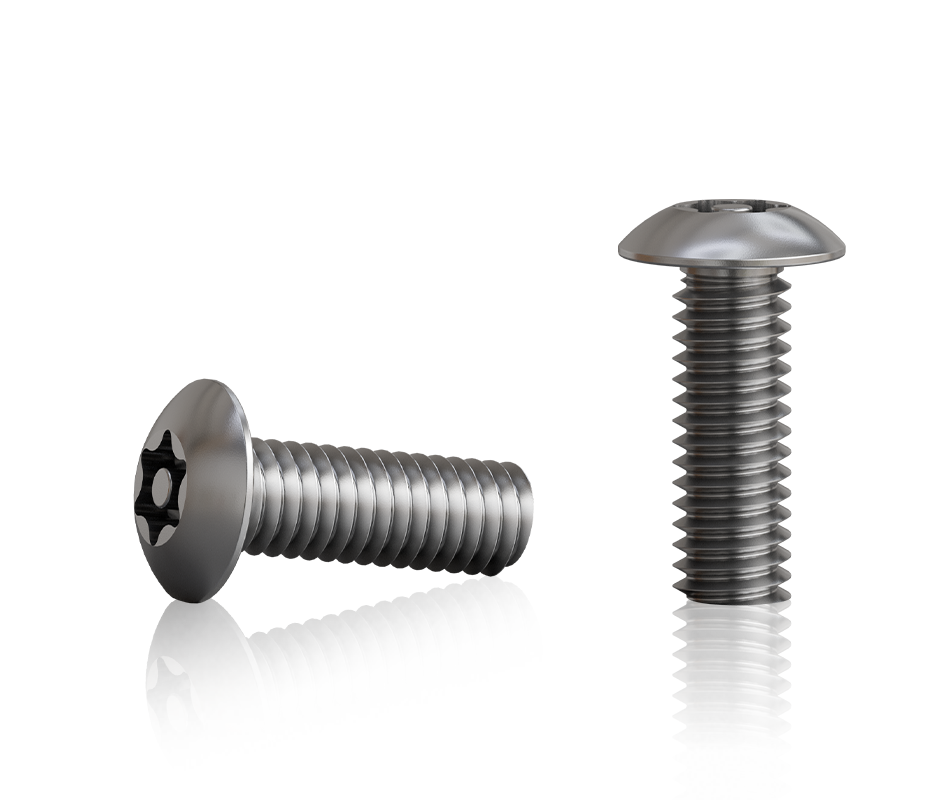

Drives

Various internal and external drives such as Phillips, slotted, hexagonal and multi-lobe drives ensure that your Special screws meet your exact requirements. Your trust and safety are important to us. We can manufacture Special screws with tamper-proof properties.

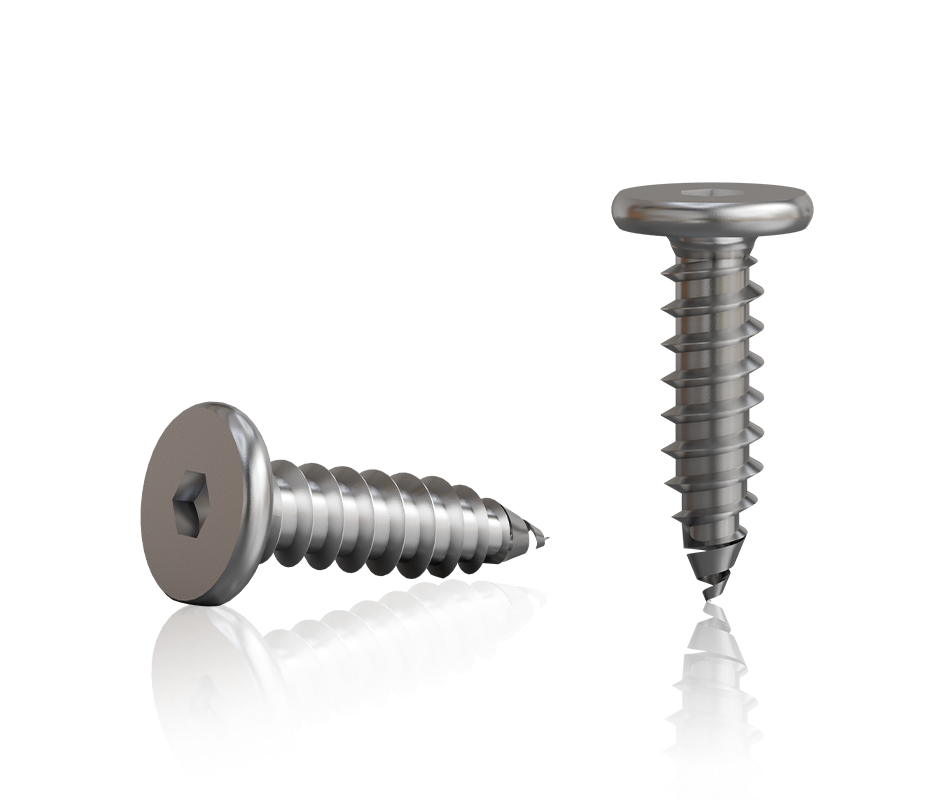

Thread

Choose the type of thread you need – whether self-tapping or machined – and we will customize it to suit your application. Options include right-hand or left-hand threads, metric or imperial, to international standards or your specific design. Perhaps you are working with a specific material such as wood, sheet metal or chipboard. As you would expect from a company with our in-depth industry knowledge, we can supply special screws that can be used for any type of material.

Properties

We manufacture special bolts and special studs that are corrosion resistant, withstand extreme temperatures or pressure or are tailored to your yield strength and tensile strength requirements. We use only the most efficient and cost-effective manufacturing methods and materials, because every Tigges Special screws is manufactured to the highest standards.

Additional equipment

Tigges is happy to offer you a range of additional equipment such as integrated lubrication grooves or cover caps. Our team will be happy to advise you on the possibilities and functionalities of other processes such as grinding, drilling or turning once your Special screws have completed the cold forming process.

A perfect fit for your industry

For demanding fields of application

Our team at Tigges can help you

Use our contact form

Technology (M) Sdn. Bhd.

Telefon: +60 (0) 5 29 22 781

Fax: +60 (0) 5 29 11 050

E-Mail: info@tigges.com.my