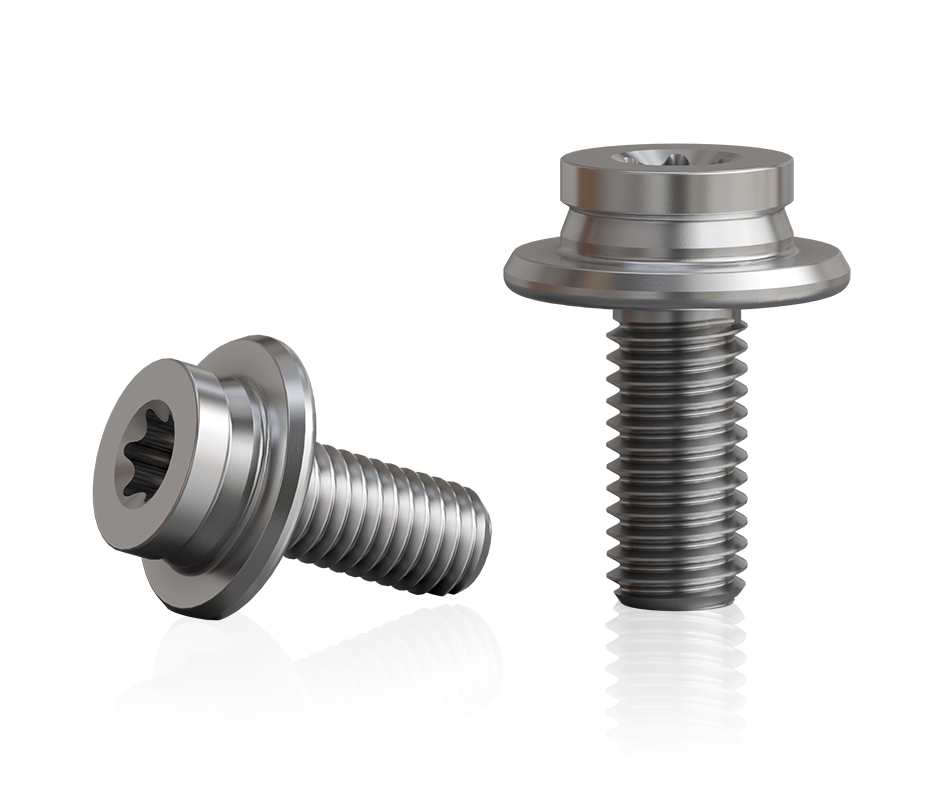

Cold-extruded parts and cold-formed parts

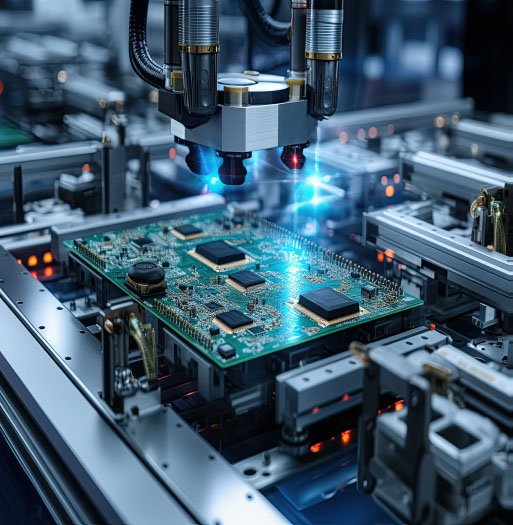

Cold-formed parts are used in almost every area of production today. Fasteners such as nuts, bolts and screws are among the most common parts manufactured using the cold forming process. Tigges produces precision-manufactured cold forming and cold-extruded parts for customers from a wide range of sectors such as the automotive industry, mechanical engineering and electrical engineering, aerospace, telecommunications, construction and power generation.

Contact usData and specifications

How are cold-formed parts manufactured?

Cold forming is a high-speed forging process in which normally coiled wire is precisely sheared to length at room temperature and then moved through a series of tool and die cavities to either increase/decrease the diameter, increase/decrease the length or remove small amounts of material by cutting or piercing. During cold forming, the metal is deformed while it is below its recrystallization point. It substantially increases tensile strength and yield strength while reducing ductility.

Advantages of high-precision cold-formed parts

There are several advantages of high-precision cold-formed parts. As the term suggests, these cold-formed parts are incredibly precise and accurate. In industries where there is no margin for error, such as construction, aerospace and automotive, this is one of the most important factors.

Compared to hot forming, cold-formed parts have a higher tensile strength thanks to the cold forming process. They are less susceptible to oxidation and have a more attractive surface finish. Because they can be produced quickly, high-precision cold-formed parts also tend to be produced more cost-effectively than hot-formed parts.

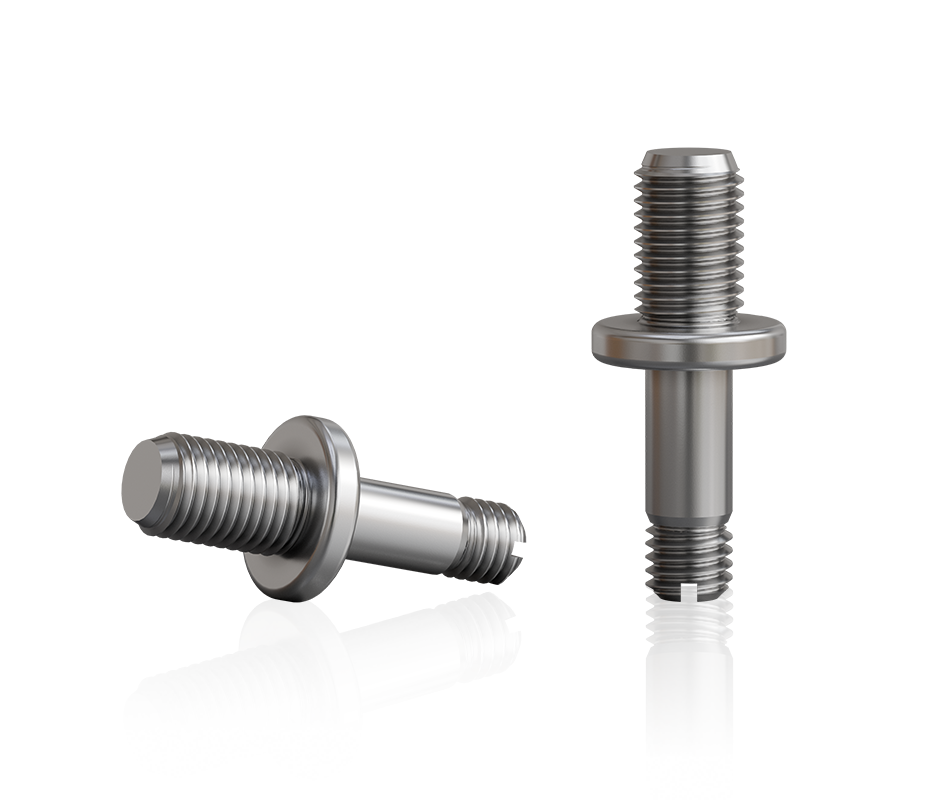

Extruded cold-extruded parts

Extrusion is a cold forming process that has become increasingly important over the last 20 years. With the latest cold forming technology in terms of machines and tools and the right tool design, it is now possible to cold form parts that in the past could only be produced using slow and costly CNC turning processes. This process therefore offers us the advantages of higher efficiency, which leads to lower costs, as well as improved mechanical properties such as strength due to the cold forming of the chosen steel material.

Although our standard range is very extensive, sometimes customized cold-formed parts are the best solution. Perhaps you need extra-large heads, different sized threads or unusual shapes or parts made from special materials. Whatever you need, Tigges can help you realize your requirements.

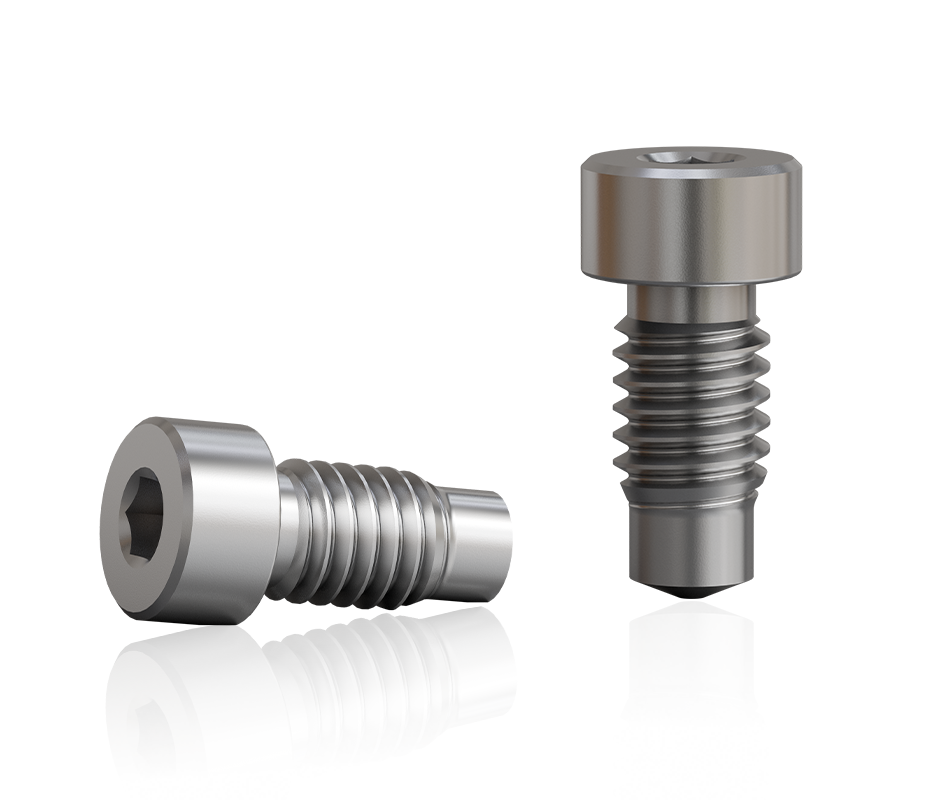

Properties

Head type is often one of the first considerations when designing a fastener. Some of the many head shapes that can be achieved through cold forming technology include countersunk, cylindrical, hammerhead, hexagon and many others.

Special screws with oversized heads are our specialty; these customer-specific parts cannot be produced using conventional cold forming processes.

A perfect fit for your industry

For demanding fields of application

Our team at Tigges can help you

Use our contact form

Technology (M) Sdn. Bhd.

Telefon: +60 (0) 5 29 22 781

Fax: +60 (0) 5 29 11 050

E-Mail: info@tigges.com.my