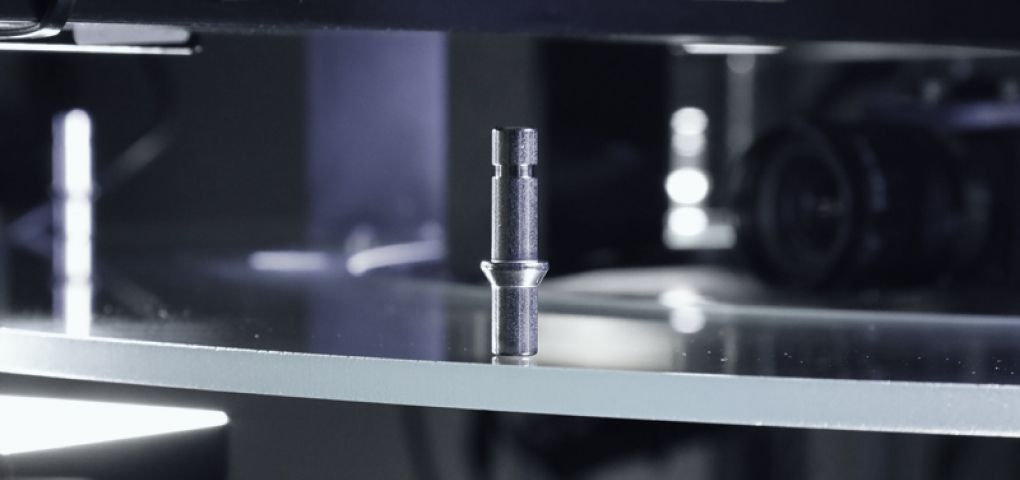

Post-processing: Functional finishing of fasteners and formed parts

Our forming technology creates the basis – post-processing provides the finishing touches. Whether threads, defined final dimensions or ready-to-assemble packaging: TIGGES covers all steps of further processing in-house. This results in fasteners and formed parts that are not only manufactured with dimensional accuracy, but also arrive at your premises ready for use.

Complex milling and drilling post-processing is also possible with our machining centers. Component reworking is not an ancillary service, but part of our integrated process chain – tailored to your requirements.

- Dimensionally accurate results: mechanical and machining processing for defined geometries

- Versatile thread options: Tapping, rolling and special shapes possible

- Optical sorting: automatic C-sorting for dimensions, shape and surface

- Assembly & packaging: pre-assembled, sorted or as component assembly

- Reliable processes: all steps documented, reliable and traceable

Our manufacturing processes

As a company with a high level of vertical integration, we offer numerous post-processing processes. They complement our forming technology and create complete component solutions from a single source.

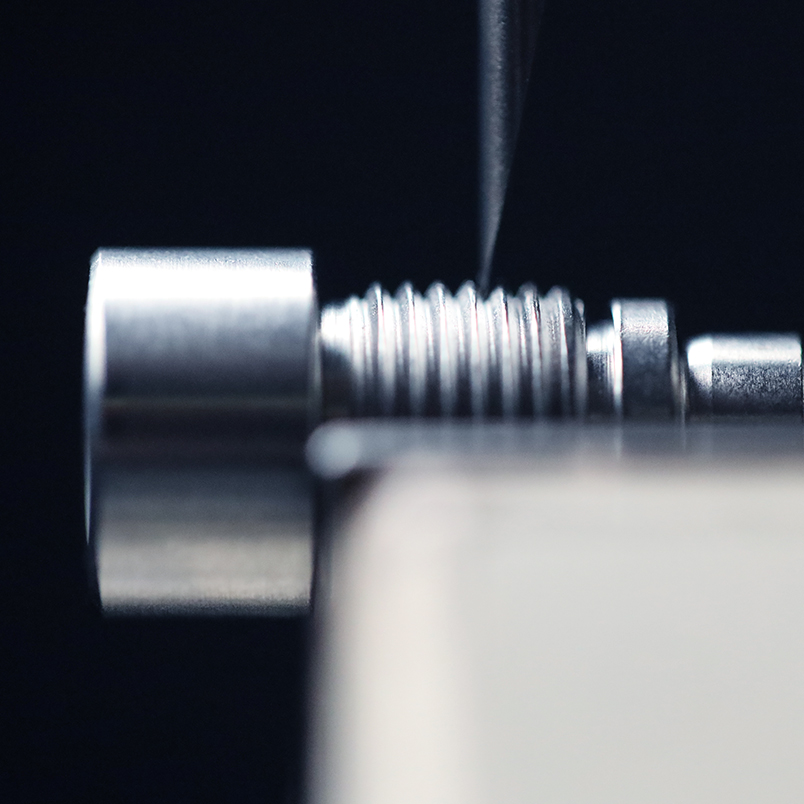

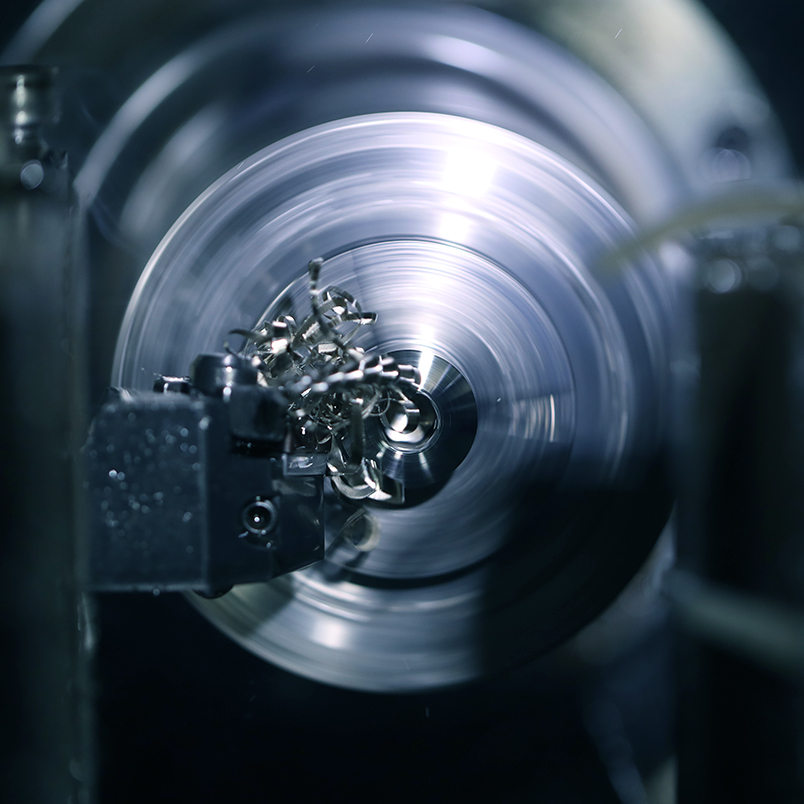

Precision work for a perfect fit

By turning, milling, grinding or drilling, your formed parts are given exactly the geometry they need for later use. This is particularly relevant for fits, head contours or specific lengths. All processing steps are carried out with tightly defined tolerances – tailored to the function and installation space.

Dimensional correction for precisely fitting formed parts

During post-turning, we precisely adjust lengths, diameters or head contours. The process is used when formed parts require tight tolerances or geometrically defined final dimensions must be achieved.

Machining is CNC-controlled and directly integrated into our production process – for consistent series quality.

Securely connected,

economically implemented

We manufacture fasteners with threads by thread cutting or rolling – depending on the requirements, material and batch size. Whether internal or external thread, metric or customer-specific: the production-oriented selection of the process ensures resilient and easy-to-assemble components.

Ready for your location

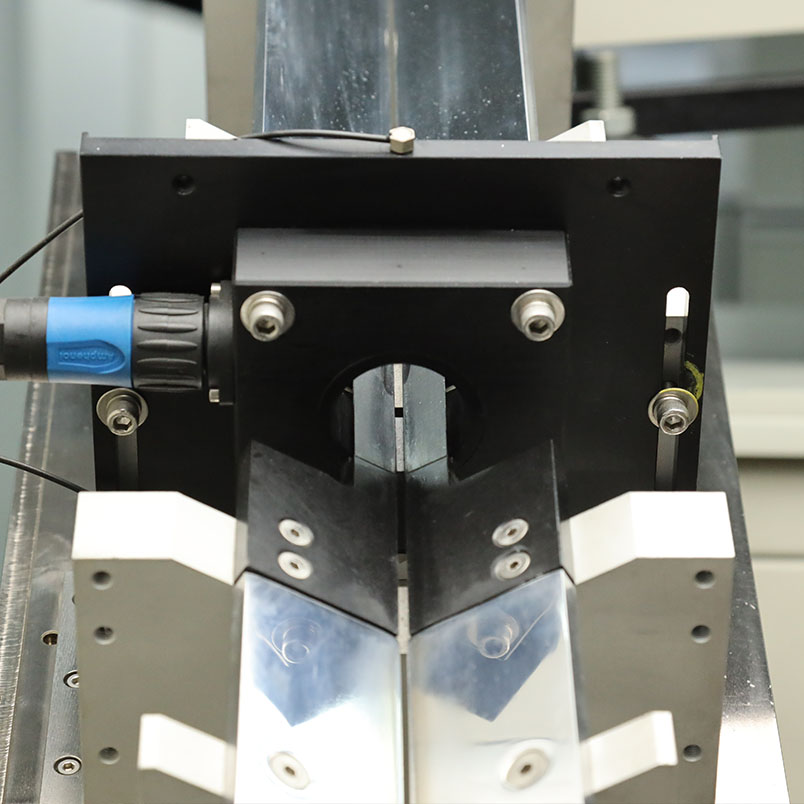

Our parts pass through automatic testing and sorting systems. Characteristics such as length, diameter, roundness or thread depth are checked with the aid of cameras. C-sorting ensures that only flawless components are further processed or delivered. They are then packaged – sorted, labeled or as a ready-to-install assembly

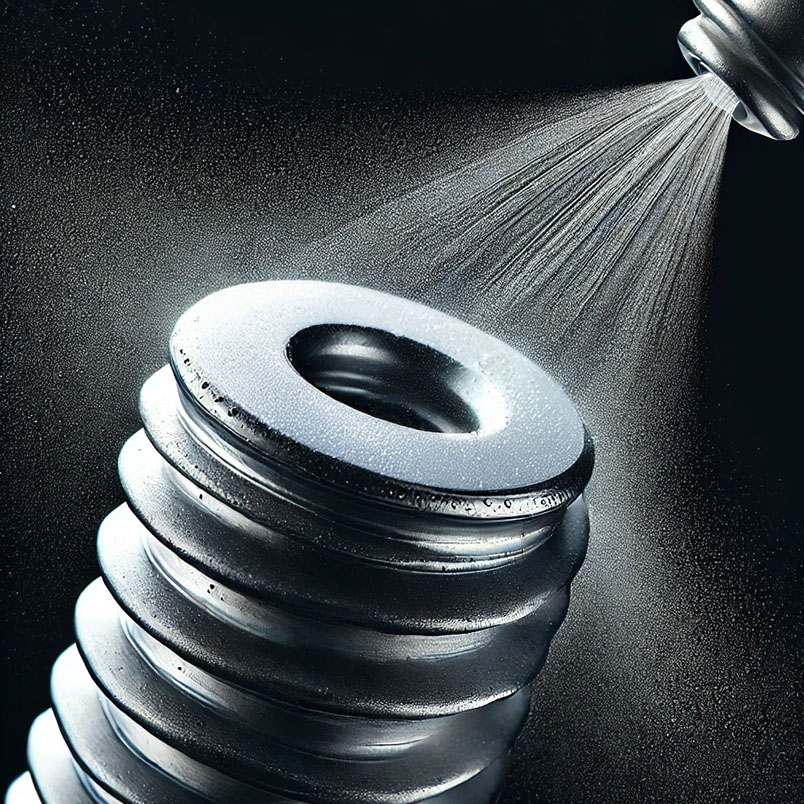

Zinc flake coating system

On request, we coat our parts internally with “zinc flake” coatings, which have considerably higher corrosion resistance than conventional zinc coatings and are also more environmentally friendly.

Thread coatings

With our internal thread coating system, we can coat threads as required, e.g. to control friction, improve running properties or to prevent loosening.

Tested quality

Also for downstream processing stepsAll post-processing is also systematically monitored. Whether this involves mechanical processing, testing or packaging: Compliance with specifications is always based on documented inspection plans.

Our quality assurance is certified in accordance with IATF 16949. It accompanies all downstream processing steps and ensures that every component meets the specifications – measurably, traceably and reproducibly.

Frequently asked questions – we are happy to answer

We offer mechanical processing such as turning, milling, drilling, grinding and thread cutting and rolling. We also sort and package to customer specifications – including visual inspection and component assembly.

Yes, we manufacture fasteners with threads directly in combination with cold forming – by cutting or rolling, depending on the component. The thread is integrated with process reliability and dimensional accuracy.

We deliver ready for assembly, individually packaged, in small load carriers or as ready-made assemblies – depending on the customer’s wishes and logistics requirements.

Our team at Tigges can help you

Use our contact form

Technology (M) Sdn. Bhd.

Telefon: +60 (0) 5 29 22 781

Fax: +60 (0) 5 29 11 050

E-Mail: info@tigges.com.my